The Top 5 Innovations in the Plastics Industry Over the Last Century — and the Next

- josh61940

- Oct 4, 2024

- 4 min read

The plastics industry has transformed our world over the past century, becoming integral to modern life. As a leading Hampshire-based plastic injection moulding company, Amey Plastics has been at the forefront of utilising these innovations to create durable, cost-effective and sustainable products for our clients. Let’s take a look at five of the most significant innovations that have shaped the plastics industry and what we predict could be the next top innovations over the next 100 years.

The Past Century's Top 5 Innovations:

1. The Invention of Bakelite (1907)

Bakelite, the first fully synthetic plastic, was invented in 1907 by Belgian chemist Leo Baekeland. It marked a turning point as the first material that was not derived from living matter, such as plants or animals. This heat-resistant and non-conductive material paved the way for the development of modern plastics. Bakelite’s impact can still be seen today in products such as electrical insulators, radios and kitchenware. Its invention set the foundation for the diverse range of plastics we use today.

2. Polyethylene's Discovery and Commercialization (1933)

Polyethylene (PE), discovered in 1933 by British chemists Eric Fawcett and Reginald Gibson, revolutionised the world of packaging. This lightweight, versatile and durable material became the backbone of plastic bags, containers and countless other everyday items. Over the decades, its adaptability has allowed it to be used in everything from pipes and wires to toys and medical devices, making it one of the most widely produced plastics globally.

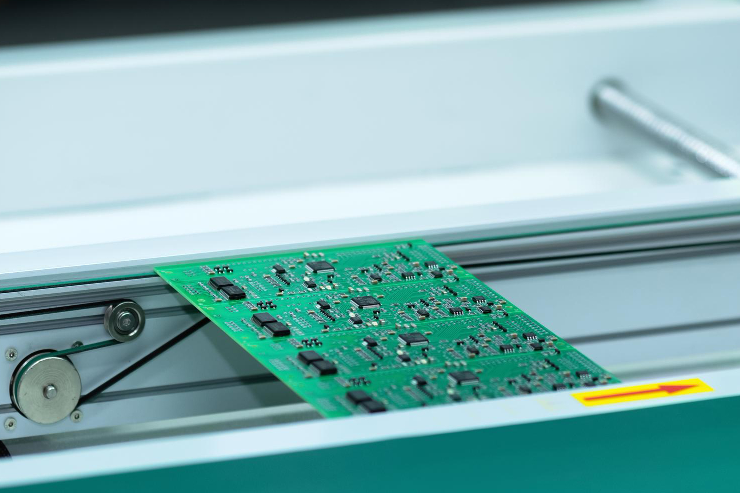

3. The Introduction of Injection Moulding (1930s)

One of the most influential technologies in the manufacturing process, plastic injection moulding was first developed in the 1930s and rapidly grew in popularity during and after World War II. It allowed for the mass production of plastic parts with precision and efficiency, transforming industries like automotive, electronics and consumer goods. Today, injection moulding remains essential in producing complex plastic components with minimal waste and here at Amey Plastics, it is a core service we provide to create high-quality, custom plastic products.

4. The Development of Polyvinyl Chloride (PVC) (1926)

Polyvinyl Chloride, or PVC, is one of the most versatile plastics ever created. Discovered by accident in 1926 by Dr. Waldo Semon, PVC quickly became a vital material due to its durability, resistance to chemicals and cost-effectiveness. Its uses range from plumbing pipes to medical equipment and even clothing. The innovation of flexible and rigid forms of PVC has helped industries across the globe save costs and produce more durable, long-lasting products.

5. The Rise of Bioplastics (21st Century)

With sustainability becoming a driving force in modern manufacturing, the development of bioplastics marks a new era for the plastics industry. Derived from renewable sources such as corn starch, sugarcane and algae, bioplastics offer an eco-friendly alternative to traditional petroleum-based plastics. These materials are designed to reduce the environmental footprint while still providing the durability and flexibility needed in applications like packaging, automotive parts and disposable items. At Amey Plastics, we’re constantly exploring the possibilities of sustainable plastic solutions to help our clients meet their eco-friendly goals.

Predicting the Top 5 Innovations for the Next 100 Years

As we look ahead, the future of plastics promises even more groundbreaking innovations, with a stronger focus on sustainability, advanced manufacturing techniques and enhanced functionality. Here are our predictions for the top five innovations that could shape the plastics industry over the next century.

1. Widespread Adoption of Fully Biodegradable Plastics

While bioplastics are already making strides in reducing the environmental impact, the future could see the creation of fully biodegradable plastics that naturally decompose without leaving harmful residues. These next-generation plastics would degrade in a matter of months, not years, breaking down into harmless organic matter, greatly reducing plastic waste and ocean pollution. This could completely revolutionise industries like packaging, agriculture and medical applications.

2. Self-Healing Plastics

Imagine a world where plastic products could repair themselves when damaged. Self-healing plastics, which are currently in the experimental stage, could become a major innovation in the coming decades. These materials would have the ability to repair micro-cracks and minor damages, significantly increasing the lifespan of plastic products and reducing the need for replacements. Applications could range from consumer electronics and automotive parts to medical devices and construction materials, offering durability that is unheard of today.

3. Advanced Recycling Techniques (Chemical Recycling)

Mechanical recycling of plastics has limitations in terms of quality and the types of plastics that can be processed. However, future innovations in chemical recycling could break down plastics to their molecular level, allowing for the recycling of a broader range of plastics with minimal loss of quality. This method could enable endless recycling loops, ensuring plastics can be reused indefinitely without degrading their properties, which would significantly lower the need for virgin plastic production.

4. Smart and Functional Plastics

As we move further into the era of smart technology, the plastics of the future could incorporate advanced functionalities such as sensors, energy storage or even the ability to change their shape or colour in response to environmental conditions. These ‘smart’ plastics could be used in fields such as healthcare (e.g., plastic materials that monitor health parameters or release medication), automotive (e.g., self-adjusting surfaces), and wearable technology. The integration of smart functions will push plastics far beyond their current uses.

5. Plastics Derived from Carbon Capture

One of the most exciting and potentially impactful innovations of the next century could be the production of plastics directly from captured carbon dioxide. By using CO2 as a raw material, manufacturers would not only reduce the amount of greenhouse gas in the atmosphere but also create a sustainable, renewable source of plastic materials. This breakthrough could significantly cut reliance on fossil fuels and help mitigate climate change, marking a huge leap forward for both the plastics and environmental industries.

An Ever Evolving Industry

The next 100 years will bring dramatic innovations in the plastics industry, with a focus on sustainability, functionality and advanced manufacturing techniques. At Amey Plastics, we are excited to be part of this future, constantly adapting and evolving to embrace these innovations, ensuring that we continue to offer cutting-edge solutions to our clients.

As always, if you have any questions or need expert assistance with your injection moulding projects, feel free to contact the Amey Plastics team on 01730 266 525 or email sales@ameyplasticsltd.co.uk. We are here to help.

Comments